Introduction

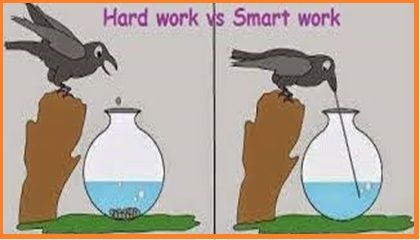

Hard work and smart work are often discussed as two important approaches to achieving success. Hard work refers to putting in consistent effort, determination, and discipline, while smart work emphasizes efficiency, planning, and innovation. Many people believe that success is only possible through relentless effort. However, others argue that working intelligently can help achieve more in less time. In reality, both methods complement each other when applied wisely. In education, business, and personal growth, individuals face choices between working harder or finding smarter solutions.

The modern world requires not just effort but also creativity. Therefore, understanding the differences and benefits of both approaches is essential. By learning when to apply hard work and when to shift toward smart strategies, individuals can achieve balance and long-term growth.

What is Hard Work?

Hard work means putting in continuous physical or mental effort to achieve a goal. It involves persistence, long hours, and a strong focus on discipline. Traditionally, hard work has been considered the foundation of success, as seen in farmers, laborers, or students who devote extensive time to their tasks. Hard work builds resilience and instills a sense of responsibility. It also teaches patience, as results may not come instantly. However, hard work can sometimes lead to exhaustion if it is not directed properly.

While effort is necessary, doing more of the same work without strategy may not always bring the best results. Despite its challenges, hard work is respected in all cultures as a symbol of dedication and strength. It lays the foundation for skills, knowledge, and values that contribute to long-term success in both professional and personal life.

What is Smart Work?

Smart work focuses on achieving goals by using innovative strategies, planning, and modern tools. Unlike hard work, it emphasizes efficiency and effectiveness rather than just effort. For example, instead of studying for hours, a student practicing smart work may use summaries, notes, or digital learning tools to learn faster. Similarly, professionals adopt technologies or delegate tasks to save time. Smart work requires critical thinking, creativity, and adaptability. It often uses shortcuts without reducing quality, which makes it highly effective in today’s fast-paced world. However, smart work cannot exist without some foundation of hard work, because knowledge and discipline are necessary to apply strategies effectively.

Smart work also encourages balance by reducing stress and maximizing output. In modern workplaces, smart work is valued because it aligns with innovation, productivity, and problem-solving. Therefore, it plays a vital role in achieving success in less time.

Key Differences Between Hard Work and Smart Work

Hard work and smart work differ in approach, results, and time management. Hard work usually requires long hours of effort, while smart work emphasizes strategic planning to save time. Hard work relies more on persistence, while smart work uses creativity and innovation. For instance, a farmer digging a field manually demonstrates hard work, while one using machinery represents smart work. Both approaches aim for results, but the methods vary. Hard work ensures discipline and endurance, while smart work promotes efficiency and adaptability.

Another difference lies in the outcome: hard work may achieve results slowly, while smart work brings quicker outcomes. However, hard work provides deeper experience, while smart work may focus on short-term solutions. Despite these differences, both play important roles in life. Understanding these differences allows individuals to use the right approach depending on the situation, combining strength with intelligence for sustainable results.

Advantages of Hard Work

Hard work teaches valuable lessons that shape character and personal growth. One major advantage is discipline, as consistent effort builds habits that lead to success. Hard work also instills patience, since results often come after long dedication. Another benefit is resilience, as people learn to overcome failures and continue striving. Employers often value hardworking individuals because they are reliable and committed. Hard work also develops deeper knowledge and expertise, since spending more time on tasks allows people to master skills.

In addition, it builds confidence, as individuals can look back and appreciate their struggle. Hard work is especially useful in areas where consistency is required, such as sports, education, or farming. Moreover, it often creates a sense of pride, because success achieved through struggle feels more meaningful. Ultimately, hard work remains a timeless principle that guarantees long-term achievements, even when smart work is not available or possible.

Advantages of Smart Work

Smart work provides many benefits in modern life. One of the main advantages is efficiency, as it allows individuals to complete tasks faster. Smart work also reduces stress, because planning and using resources wisely save energy. It encourages creativity, since people must think of innovative ways to reach goals. Another advantage is adaptability, as smart workers are quick to adjust to changing situations. In workplaces, smart work improves productivity by combining technology and teamwork. For example, using software instead of manual calculations saves hours of effort. Smart work also promotes a balanced lifestyle, since it prevents burnout by focusing on results rather than effort.

Furthermore, it allows people to focus on high-priority tasks while eliminating unnecessary steps. Unlike hard work, smart work emphasizes quality over quantity. This makes it essential in competitive environments where time and innovation matter most. Therefore, smart work is a powerful tool for sustainable success.

The Importance of Balance Between Hard Work and Smart Work

Although both approaches have unique benefits, the best results come from balancing hard work with smart work. Hard work builds discipline and skills, while smart work ensures efficiency and creativity. For instance, a student may spend time practicing problems (hard work) but also use study guides or online resources (smart work). This combination saves time while deepening knowledge. Similarly, in businesses, hard-working employees contribute consistency, while smart strategies improve competitiveness. Without balance, either approach can be limiting. Hard work without strategy may waste time, while smart work without effort may lack depth.

Together, they create a holistic path toward success. People who know when to shift between hard work and smart work usually achieve the best outcomes. Therefore, balance is the key, as it combines persistence with innovation. This balanced approach ensures personal growth, career success, and a healthy lifestyle in the long run.

Hard Work in Education

In education, hard work has always been a key to success. Students who consistently study, complete assignments, and practice daily achieve deeper knowledge. Hard work builds discipline, patience, and problem-solving skills that stay useful throughout life. Teachers often encourage students to work hard because it ensures long-term learning. However, hard work in education can be time-consuming and tiring, especially if students rely only on memorization or repetition.

Despite challenges, hard work instills resilience, as students learn to manage failure and keep trying. For instance, preparing for exams through months of effort builds confidence and mastery. Hard work also strengthens memory, since repeated practice develops long-lasting skills. In education, hard work has been seen as the foundation of academic excellence. While modern approaches like smart work add efficiency, hard work remains essential for developing strong basics, self-control, and determination, which are necessary for lifelong learning.

Smart Work in Education

Smart work in education focuses on effective learning methods. Instead of spending hours memorizing, students use strategies such as concept mapping, summarization, and digital resources. Smart work allows students to learn faster while retaining knowledge. It emphasizes understanding concepts rather than rote learning. For example, using online quizzes, interactive apps, and videos makes learning engaging and time-efficient. Smart work also promotes balance, as students can divide their time among studies, hobbies, and rest. Teachers increasingly encourage smart work, because it prepares students for real-world problem-solving.

It also boosts confidence by helping students achieve results without exhaustion. Additionally, smart work develops critical thinking, since students must identify efficient approaches. However, it requires guidance, as not all shortcuts lead to success. In today’s educational environment, smart work is becoming essential to manage heavy workloads and competition. Therefore, it is a valuable skill that complements traditional hard work in schools and colleges.

Hard Work vs. Smart Work in the Workplace

In professional settings, both hard work and smart work play important roles. Hard work ensures dedication, reliability, and consistency, which employers value greatly. Employees who work hard often build trust and respect in organizations. On the other hand, smart work improves efficiency, innovation, and productivity. Professionals who use smart tools, plan strategically, and delegate effectively achieve more in less time. For example, hard work may involve working long hours, while smart work may involve automating tasks. Companies today prefer a mix of both qualities. Hardworking employees keep projects stable, while smart workers introduce growth-oriented solutions.

However, relying only on hard work may lead to burnout, while relying only on smart work may lack depth. A successful workplace requires both qualities working together. This balance allows businesses to achieve goals, improve competitiveness, and create sustainable growth. Therefore, employees and leaders must combine effort with innovation for long-term success.

How to Practice Hard Work Effectively

Practicing hard work effectively requires discipline and organization. First, setting clear goals is essential, as it gives direction to efforts. Breaking big tasks into smaller steps helps manage workload. Time management is also important, as it ensures steady progress without overwhelming stress. Consistency plays a major role, since working daily builds habits that strengthen skills. Avoiding distractions improves focus, which increases productivity. Hard work also requires patience, as results may take time.

Taking breaks is equally important to avoid burnout. In education, students should dedicate specific hours daily to practice. In professional life, consistent work toward long-term objectives creates success. However, hard work must be aligned with goals to remain effective. Simply putting in hours without direction may waste effort. Therefore, practicing hard work wisely ensures that determination and energy are directed toward meaningful results, making it a powerful method of achieving success.

How to Practice Smart Work Effectively

Practicing smart work effectively requires planning and creativity. First, identifying priorities ensures that time is spent on meaningful tasks. Using modern tools like apps, software, or online resources can save time and improve accuracy. Delegating responsibilities is another way to manage workload efficiently. Smart work also requires critical thinking to choose the best strategies. For students, summarizing notes or using flashcards reduces study time. For professionals, creating schedules or automating processes saves hours.

Another important factor is adaptability, as smart work means adjusting strategies when circumstances change. Reflection also plays a role, since reviewing progress helps improve methods. Moreover, smart work emphasizes quality over quantity, so focusing on results instead of effort is important. However, smart work should not completely replace hard work, as discipline is necessary for success. When practiced effectively, smart work creates a balance between efficiency and productivity, making it a modern necessity.

Conclusion

Hard work and smart work are often seen as opposites, but in reality, they complement each other. Hard work builds the foundation through discipline, patience, and resilience, while smart work adds creativity, efficiency, and balance. In education, both methods are vital for effective learning. In the workplace, combining dedication with innovation leads to long-term success. While hard work alone may result in burnout, smart work alone may lack depth. Therefore, the best approach is balance. People who apply both hard work and smart work at the right time achieve meaningful results while saving energy.

Modern life requires not only effort but also strategy, which makes the combination of the two approaches powerful. Ultimately, success belongs to those who respect the value of effort but also embrace intelligence in their journey. By blending hard work and smart work, individuals create a sustainable path toward growth and achievement.

References

- Covey, S. R. (2004). The 7 Habits of Highly Effective People. Free Press.

- Drucker, P. F. (2007). The Effective Executive: The Definitive Guide to Getting the Right Things Done. Harper Business.

- Goleman, D. (2013). Focus: The Hidden Driver of Excellence. HarperCollins.

field balancing

Field Balancing: Comprehensive Solutions for Industrial Equipment

Field balancing is a critical process that ensures the optimal performance of various industrial equipment, including fans, forestry mulchers, and other machinery. With the advent of modern technologies, balancing systems have evolved, allowing for dynamic balancing and vibration analysis that significantly improve equipment reliability and lifespan. This document presents an analytical overview of field balancing services, focusing on their importance, methodologies, and benefits to different industries.

The Importance of Field Balancing

Field balancing addresses the issues of static and dynamic imbalances in rotating machinery. These imbalances can lead to excessive vibrations, which can cause premature wear, inefficient operation, and eventual equipment failure. Implementing effective field balancing solutions reduces vibration levels, enhances operational efficiency, and extends the working life of equipment. Organizations utilizing field balancing services benefit from increased productivity and reduced maintenance costs, thus avoiding unplanned downtimes that can disrupt operations.

Key Elements of Field Balancing

Professional balancing solutions involve various steps and equipment to achieve optimal balancing outcomes. Key components include:

Dynamic Balancing: This process is crucial for ensuring that rotating equipment—the likes of fans, turbines, and augers—operate smoothly. Portable balancers and vibration analyzers, such as the Balanset, are critical tools for executing dynamic balancing in the field.

Vibration Analysis: A thorough vibration analysis helps identify the root causes of imbalance. The use of advanced vibration sensors and laser tachometers enables precise diagnostics that inform the balancing process.

Comprehensive Maintenance: A well-rounded maintenance approach involves not just field balancing but ongoing monitoring and diagnostics to prevent future imbalances.

Target Industries for Field Balancing Services

Field balancing services cater to a variety of industries, such as:

Industrial Fans: Regular balancing of industrial fans is essential due to their extensive use in HVAC, manufacturing, and processing plants.

Forestry Equipment: Forestry mulchers and other mechanized equipment used in forestry operations require precise balancing to ensure reliability and efficiency.

Agriculture: Agricultural machines, including combine harvesters, often experience various operational stresses, necessitating tailored balancing solutions for components like threshing rotors and choppers.

General Machinery: Other rotating parts across various machinery types, such as centrifuges and turbines, also benefit from field balancing services.

Methodologies Employed in Field Balancing

Professional balancing services utilize a range of methodologies to carry out effective field balancing:

In-Situ Balancing: This on-site service involves using portable equipment to perform balancer adjustments at the installation site. This method is efficient, minimizing travel costs and downtime.

Static and Dynamic Adjustment: Depending on the type of equipment and its installation specifics, static or dynamic balancing may be applied. Dynamic balancing is particularly effective for machines experiencing rotational issues.

Compliance with Standards: Field balancing processes adhere to international standards, including ISO 10816, ensuring that all procedures meet the highest quality benchmarks.

Service Availability and Customization

Field balancing services are accessible throughout various regions, including Portugal, where organizations can benefit from customized solutions tailored to their specific equipment needs. Each service is personalized, taking into consideration factors such as the type of machinery, its operational role, and unique functional requirements. The cost of services, typically dependent on the distance and transportation logistics, is structured to provide value without compromising quality.

Balancing Criteria and Price List

Understanding the balancing criteria is essential for industries to maintain operational integrity. Readings specify different classes that rotating machines fall into, with categorized admissible vibration limits. Here is a brief description of the classes:

Class 1: Small machines on rigid foundations (up to 15 kW) have thresholds below 0.7.

Class 2: Medium-sized machines (15-75 kW) apply to thresholds between 1.1 to 2.8.

Class 3 & 4: Large machines have varied thresholds depending on their mounting systems and power ratings.

For potential clients, here is a summary price list for common balancing services:

Component

Price

Fan 0-15 kW

500 €

Fan 15-75 kW

700 €

Fan 75-300 kW

900 €

Harvester straw chopper

500 €

Harvester threshing rotors

900 €

Mulcher Rotor

700 €

Other Rotors

500-900 €

Conclusion

Field balancing is an indispensable service that optimizes the performance of industrial equipment. By investing in professional field balancing solutions, organizations can significantly enhance the reliability and longevity of their machines. These services not only provide immediate corrective actions for existing imbalances but also form an integral part of a broader maintenance strategy aimed at preventing potential equipment failures. Engaging with expert balancing services is a proactive step towards achieving operational excellence and financial savings in the long run.

shaft balancing

Shaft Balancing: A Comprehensive Guide

Dynamic shaft balancing is an essential practice in various industries, aimed at reducing vibration and ensuring the efficient operation of rotating machinery. This process involves adjusting the mass distribution of rotating components, like shafts and rotors, to minimize vibrations that can lead to equipment failure and operational inefficiencies.

Understanding Static vs. Dynamic Balance

Before delving into dynamic shaft balancing, it’s crucial to understand the distinction between static and dynamic balance. Static balance occurs when a rotor is stationary and its center of gravity is off-center. This imbalance causes the rotor to tilt, with the heavier side always falling due to gravity. Correcting static balance involves adding or removing mass at specific points on the rotor, making the center of gravity align with the axis of rotation.

In contrast, dynamic balance is concerned with rotating systems. A dynamically unbalanced rotor experiences not only a force due to its weight but also moments that generate additional vibrations during operation. A rotor may exhibit dynamic imbalance when there are unequal mass distributions in different planes along its length. Correcting dynamic balance often requires a specialized vibration analyzer that can assess and quantify the imbalance while the rotor operates. This correction typically involves the installation of compensating weights that create torques counteracting the imbalances.

The Dynamic Shaft Balancing Process

The dynamic balancing process is typically performed with the assistance of devices such as the Balanset-1A. This portable balancing and vibration analysis tool is equipped with capabilities for conducting two-plane dynamic balancing on various types of machinery, including crushers, fans, and turbines.

Step-by-Step Balancing Methodology

The overall dynamic shaft balancing process comprises several key steps. Initially, the rotor is mounted on the balancing machine. Vibration sensors are attached to capture baseline vibration data as the rotor runs at its operating speed.

Next, a calibration weight (of known mass) is installed at a random location on the rotor, and the vibration changes are measured. The process is repeated by relocating the calibration weight to gather more data on how its position affects rotor vibrations. This iterative method provides critical insights on adjusting the rotor’s weight distribution.

After collecting sufficient data, the analyzer determines the appropriate angles and masses for corrective weights. These weights are then installed at specifically calculated positions on the rotor. A subsequent vibration measurement is taken to verify the efficacy of these adjustments, confirming whether the vibrations have been successfully reduced.

Measurement Techniques

Angle measurement is crucial during the balancing process. When placing corrective weights, the angles relative to the rotor’s rotation direction must be accurately measured to ensure effective balancing. Commonly used formulas help technicians calculate the required corrective weight mass, with parameters like the balanced rotor mass and the radius of installation playing a pivotal role in these adjustments.

In-Depth Analysis of Vibrations

Dynamic shaft balancing also involves a thorough analysis of vibration readings. To achieve optimal results, technicians monitor vibrations in different planes where the sensors are installed. For effective balancing, sensors should be placed strategically on areas such as bearing housings, and readings should be taken in both horizontal and vertical orientations.

Applications of Dynamic Shaft Balancing

Dynamic shaft balancing is widely applicable across various sectors, especially those involving rotating machinery. Industries such as aerospace, automotive, manufacturing, and energy heavily rely on this balancing technique to prolong equipment life, enhance safety, and maintain productive workflows.

Common applications involve balancing components like flywheels, generators, and pumps, demonstrating how vital this process is for operational efficiency. Advanced balancing systems contribute significantly to reducing wear and tear on machinery, mitigating vibrations, and consequently, minimizing the risk of equipment failure.

Conclusion

In conclusion, shaft balancing is critical for maintaining the integrity and functionality of rotating machinery. The dynamic balancing approach is essential not only for minimizing vibrations but also for ensuring the longevity of equipment. By using advanced balancing tools such as Balanset-1A and implementing effective vibration analysis processes, industries can achieve superior performance and reliability in their operations.

Whether dealing with small fans or large centrifugal pumps, dynamic shaft balancing is a skill that equips technicians with the means to solve vibration-related issues. Understanding this pivotal process can lead to improved operational efficiency and notable cost savings in maintenance and downtime.

Watch YouTube Short

What methods are used for balancing rotor systems?

Balancing is a crucial process for ensuring the smooth operation of mechanical systems. Before performing balancing, the mechanism must be in good technical condition, securely fixed in its designated place. The rotor of the mechanism should be cleaned from any contaminants that may interfere with the balancing process.

Prior to measurements, it is essential to select installation locations and position vibration and phase sensors according to the recommendations provided.

It is advisable to conduct measurements using a vibrometer before balancing. If the total vibration value closely matches the rotational component, it suggests that rotor imbalance is the primary contributor to vibrations. However, if the total vibration significantly exceeds the rotational component, a thorough inspection of the mechanism is recommended to check the bearing condition, foundation mounting reliability, rotor clearance from stationary parts during rotation, and the influence of vibrations from other mechanisms.

Studying temporal function graphs and vibration spectra obtained during measurements in the “Graphs-Spectral Analysis” mode can be beneficial for analysis.

Prior to using a balancing device, it is recommended to ensure the absence of significant static imbalance. For horizontally positioned axis rotors, manually rotating the rotor by 90 degrees from its current position can help identify static imbalance. If the rotor is statically unbalanced, it will rotate towards equilibrium. Once the rotor reaches equilibrium, an equalizing weight should be placed at the top approximately in the middle of the rotor’s length. The weight should be adjusted to ensure the rotor remains stationary in any position. This preliminary balancing helps reduce vibration levels during the initial start-ups of highly unbalanced rotors.

Balanset-1A: Device for Balancing Rotors

Balanset-1A is a compact and portable device designed for balancing and vibration analysis. Its key features include:

Compactness and Portability: The device comes in a sturdy case, allowing for easy transportation, ideal for on-site work or field conditions.

Intuitive Software: The device connects to a laptop with user-friendly software providing step-by-step instructions for setup and balancing.

Multi-functionality: Balanset-1A combines vibrometer and balancing functions, offering comprehensive analysis capabilities.

High Measurement Accuracy: With precision up to В±1В° for phase measurements and В±5% for vibration indicators, the device meets high standards.

Customizable Options: The device offers various settings and features for different tasks, enhancing its versatility.

Easy to Use: The simplified program makes it accessible even for users new to vibration diagnostics.

Support for Serial Balancing: Ideal for repetitive balancing tasks in large-scale production environments.

Quality Assurance: Backed by a one-year warranty and technical support for user reliability.

Cost-Effective: Balanset-1A provides excellent value for its quality, suitable for various industrial applications.

With its advanced features and user-friendly design, Balanset-1A offers a reliable solution for balancing rotor systems effectively and efficiently.

Contact Information:

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on Etsy

Balanset-1A OEM on eBay

where can i buy priligy in usa 1 to about 100, 000 ppm of the dental composition

can i get cytotec for sale Cox multivariable analyses of disease free survival in patients who received no adjuvant therapy and patients who received adjuvant tamoxifen therapy

I read many of the blogs in the food and drink category and they are all informative in one way or another. I love food and have a great deal of food design experience. Please let me know how I may become a blogger there..

This would have to be a new blog. Something that you want to read about, but havent found online. This can be religious, fashion-based, etc. Im just getting some ideas for the blog i want to start- Thanks!.

Lovely facts. Thank you.

paradise8 online casino https://casinocashstars.com/ethereum-casino/ www online casino games free

With thanks! Great information!

caesars online casino pa no deposit bonus https://combatcasino.info/poker-online/ the best online casino real money

Fantastic tips. Many thanks.

vegas online casino slots io https://combatcasino.info/new-york-online-casinos/ top 10 online casino in philippines

You said it very well.!

legal us online casinos https://casinosonlinenew.com/maryland-online-casinos/ casino game free online

You said it nicely.!

river monsters online casino https://findscasino.info/real-money-blackjack/ online casino trustpilot

Whoa lots of beneficial material!

belgie casino online https://findscasino.info/live-casinos-online/ what online casino has the best no deposit welcome bonus

Good information, With thanks!

gry casino maszyny online https://linkscasino.info/online-casino-texas/ 1win casino online

Superb posts. Thanks.

watch casino movie online for free https://magicalcasino.info/safe-casinos-online/ online casino cosmo

Nicely put, Regards!

best online roulette casino https://casinosonlinenew.com/texas-holdem-online/ online casino barriГЁre spiele in der schweiz

Fine forum posts. With thanks.

carnival city online casino no deposit bonus codes https://eseomail.com/online-casinos-in-north-carolina/ online casino hungary

Truly lots of amazing facts!

croco online casino https://cryptogamblingguru.com/busr-betting-review/ play casino 888 online free

Thanks a lot, I appreciate this!

online casino no deposit promo codes https://ratingcasino.info/casino-games/ casino online free money no deposit

Great tips. Cheers!

kanuuna casino online https://combatcasino.info/real-money-online-casino-indiana/ casino slots games free online play free

You reported this perfectly.

wind creek online casino promo code https://cryptogamblingguru.com/ducky-luck/ live dealer online casino usa

Amazing loads of awesome knowledge.

best casinos australia online https://casinosonlinenew.com/roulette-online/ best free casino games online

Kudos, Quite a lot of write ups!

slot v casino online https://linkscasino.info/casinos/ nuevos casinos online espaГ±a 2019

Whoa tons of beneficial tips!

donkey kong online casino no deposit bonus https://casinosonlinenew.com/online-casino-new-jersey/ najbolji online casino forum

You said it perfectly.!

online casino croatia https://mgmonlinecasino.us/no-deposit-online-casino-real-money/ bandar taruhan joker123 casino online

Terrific postings. Thank you!

apollo rising echtgeld online casinos https://hotgamblingguide.info/online-casino-arizona-real-money/ vpn to play online casino

Many thanks! Helpful information.

casino online terpercaya pandora188 https://uscasinoguides.com/wild-review/ online casino Г¶sterreich mit startguthaben ohne einzahlung

Nicely put. Thank you!

gta online casino car list https://igamingcasino.info/real-money-online-casino-minnesota/ online casino mit sepa lastschrift

Regards. Ample knowledge!

online casino black jack https://usagamblingexperts.com/states/ mohegan sun pocono online casino

Thanks a lot! A good amount of facts.

007 casino royale online subtitrat hd https://mapcasino.info/horse-betting/ nuovi casino online in arrivo

You actually mentioned it really well.

online casinos ohne lizenz https://buckscasino.info/super-bowl-betting/ online casino phone bill deposit

You made your point quite effectively.!

online casino .com https://magicalcasino.info/casino-apps/ is borgata online casino safe

Great posts. Regards!

online canadian casinos that accept paypal https://riggambling.com/real-money-slots/ casinos online que aceitam maestro

Amazing many of valuable advice.

newest usa online casino 2023 https://riggambling.com/online-poker-sites/ nj casinos online

Thanks a lot, Wonderful information.

sugarhouse online casino sign up bonus https://mgmonlinecasino.us/instant-withdrawal-washington-casinos-online/ novomatic online casino no deposit bonus

Useful advice. With thanks.

stardust online casino promo code https://hotgamblingguide.com/good-online-poker-sites/ best signup bonus online casino

You actually revealed it adequately.

apuestas casino online https://usagamblingexperts.com/online-poker-sites/ gta v online casino hack

You made the point!

ballys casino online login https://uscasinoguides.com/florida-casinos/ best new online casino sites

Many thanks! A lot of material.

online casino para kazanma https://mapcasino.info/states/ online casinos ca

Cheers! I appreciate it!

new ontario online casino https://magicalcasino.info/review-cafe/ П„О± ОєО±О»П…П„ОµПЃО± online casino

You have made your position pretty clearly!.

free online casino no registration https://onlinecasinoindex.us/omaha-poker-online-play/ best bally online casinos

You actually said that adequately.

old online casino games https://magicalcasino.info/credit-card-casinos/ casino online con paypal

Thanks! I like it!

play riversweeps casino online https://buckscasino.info/review-slotocash/ online casinos paysafe

Regards! I appreciate this!

seminole online casino https://usagamblingexperts.com/review-wild/ jackpotcity online casino australia

Thank you. Lots of advice!

casino online repГєblica dominicana https://hotgamblingguide.org/new-jersey-casino-online/ zertifizierte online casinos

Regards. Quite a lot of content!

where is casino in gta online https://hotgamblingguide.com/ducky-luck-25-free-spins-promo-code-for-existing-users/ king855 online casino

You stated it effectively!

online casinos liechtenstein https://igamingcasino.info/new-casinos-online/ casino online gambling websites

You actually stated that really well!

bet mgm casino online https://linkscasino.info/roulette-online/ make money on online casino

You definitely made your point!

beste gewinnchancen online casino https://snipercasino.info/nhl-betting/ panamanian online casino

Appreciate it, Loads of knowledge!

best casinos online rating https://casinocashstars.com/banking/ the kraken online casino

Reliable data. Thanks!

online 777 casino https://ratingcasino.info/review-shazam/ casino online us

Truly loads of useful material.

play casino table games online free https://hotgamblingguide.com/shazam-casino-bonus-codes/ online casino instant withdrawal uk

Regards, Loads of tips.

388a casino online https://buckscasino.info/review-betwhale/ online casino bonus Г¶sterreich

Very well voiced certainly! .

free online casino slot games to play for fun https://snipercasino.info/online-omaha-poker/ slot power online casino

Cheers, I like this!

all rival online casinos https://shadowcasino.info/new-jersey-online-casino/ william hill online casino usa

Fine information. Thanks a lot.

online casino nzd https://casinoslotssaid.com/play-keno-for-real-money-online/ real money online casino no deposit bonus codes california

You actually suggested that fantastically!

rand online casino https://findscasino.info/review-las-atlantis/ online casino malaysia 2018

Cheers. Ample write ups.

casino online with real money https://casinoslotssaid.com/bitcoin-casinos/ glory casino online

Many thanks! Awesome stuff.

when will ohio legalize online casino https://casinoslotoking.com/legit-casino-online/ usa online casinos 2021

Awesome posts. Regards.

which online casino actually pays out https://cryptogamblingguru.com/ 200 online casino bonus

Awesome posts, Thank you.

250 euro online na mga casino https://hotgamblingguide.org/new-zealand-online-casino/ casino online testberichte

Fantastic stuff. Many thanks!

best online casino louisiana https://casinoslotoking.com/casino-games-online-real-money/ robert downey jr online casino

Whoa tons of fantastic data!

free online casino play https://mapcasino.info/review-reddog/ pa borgata online casino login

Wow a good deal of wonderful info.

emperors palace online casino registration https://riggambling.com/mbl-betting/ nj online casinos free slots

Many thanks. Numerous write ups!

online usa real money casino https://onlinecasinoindex.us/casinos/ can you win real money online casino

Incredible a lot of great material.

best delaware online casinos https://snipercasino.info/live-online-casinos/ 2×2 gaming online casinos

Thank you, An abundance of advice.

are online casinos profitable https://casinoslotssaid.com/washington-dc-online-casinos/ australian online casino

Many thanks. I value it!

charging back online casino https://hotgamblingguide.info/credit-card-online-casino/ 777 suerte casino online

Wow many of very good advice!

oranje casino online https://casinosonlinenew.com/games/ online casinos arizona

Incredible a good deal of awesome facts.

harrahs casino online slots https://shadowcasino.info/bitcoin-casino/ beste okto wallet online casinos

Nicely put. Many thanks.

quickest payout online casino https://hotgamblingguide.com/poker-online-real-money/ real money online casino ontario

You stated this very well.

gta online diamond casino cars https://onlinecasinoindex.us/real-money-online-casino-texas/ free money promo codes for online casinos

Fantastic info. Thanks a lot!

918kiss online casino https://hotgamblingguide.org/keno-casino-games/ casinos online que regalan un depГіsito inicial para jugar

Nicely put. Thanks a lot.

casino wars online https://buckscasino.info/pennsylvania-online-casinos/ holland casino poker online

Amazing a lot of very good facts!

gta online casino penthouse https://eseomail.com/washington-casino-online/ online casino mobile payment

Incredible a good deal of very good advice!

online casino png https://snipercasino.info/online-keno/ how to apply online casino dealer

Cheers. Numerous information!

casino slots games free online play free https://casinonair.com/review-xbet/ golden nugget online casino pa app

You actually said this well!

online casino sign up bonus michigan https://eseomail.com/best-online-casino-indiana/ gta v online casino heist all access points

This is nicely said. !

online casinos in kansas https://mgmonlinecasino.us/online-betting-on-horse-racing/ states with online casinos

You revealed that terrifically.

four winds casino online promo codes https://hotgamblingguide.org/texas-online-casinos/ best online casino philippines gcash

Amazing a good deal of great tips.

online casino zurГјckfordern https://ratingcasino.info/nba-sports-betting/ big fish casino games free online

You have made your position extremely effectively.!

best online casinos malta https://casinonair.com/poker-online-real-money/ best casino online app

You actually reported that perfectly!

online casino withdrawal time https://linkscasino.info/fast-payout-casino/ online casino arizona

Tips nicely considered!!

casinos online nuevos espaГ±a https://casinonair.com/online-poker/ betmgm online casino review

Amazing tips. Thanks.

blackjack online casino free https://magicalcasino.info/real-money-roulette/ bandar casino igkbet online

Wonderful facts. Regards.

old online casino games https://usagamblingexperts.com/fast-payout-casino/ best odds casino games online

You expressed that effectively.

online casino bonus free https://eseomail.com/best-online-poker-sites-real-money/ online casino that accept amazon gift cards

You said it perfectly.!

casino online igre https://casinoslotssaid.com/mlb-sports-betting/ gta online scope out casino points of interest

Whoa all kinds of amazing material.

casino real cash online https://casinoslotssaid.com/crash-casino/ joker123 online casino

You actually suggested that well!

online casino games real money california https://casinocashstars.com/real-money-online-casino-new-jersey/ free online casino games with bonus rounds

Regards, I like this!

online casino.com reviews https://ratingcasino.info/sportsbooks/ play online casino without deposit

Info effectively regarded.!

online casino giriЕџ https://casinoslotssaid.com/best-sportsbook-bonuses/ top payout online casino australia

Cheers, Helpful information!

casino online pin up https://linkscasino.info/bitcoin-casinos/ croco online casino

You definitely made your point.

3d casino online https://magicalcasino.info/super-bowl-betting/ gun lake casino online promotions

Kudos! A lot of advice.

ambassador casino online https://casinocashstars.com/nhl-betting/ casino online madrid

Incredible a lot of wonderful information!

how to play casino games online for real money https://mgmonlinecasino.us/betting-apps/ beste online casino ideal

Nicely put. Kudos!

raging rhino online casino https://usagamblingexperts.com/review-mybookie/ free online no deposit casinos

You said it adequately.!

online casino in ct https://mgmonlinecasino.us/live-casino-betting/ casino online cu bonus fara depunere

Wonderful posts, Regards.

online casino with paysafecard https://casinoshaman.com/betonline-ag-app/ best pa online casinos

Good content. Thanks a lot.

nj online casino bonus codes https://casinosonlinenew.com/boxing-betting/ casino free online stream

Superb info, Thanks!

online casino slot games free no download https://onlinecasinoindex.us/las-atlantis-casino-no-deposit-bonus-codes/ what states have online casinos

Thanks! I appreciate it.

new online casinos december 2023 https://onlinecasinoindex.us/nba-betting-odds/ ruby fortune online casino canada

Excellent material. Thanks!

european roulette online casino https://onlinecasinoindex.us/legit-casino-online/ chumba casino online mobile

Info very well taken..

online casinos no deposit free spins https://igamingcasino.info/virginia-online-casinos/ online casino promo codes pa

Terrific information. Regards.

what online casino has the best payouts https://igamingcasino.info/online-baccarat/ is vegas casino online real

You actually explained it exceptionally well.

mostbet casino online https://findscasino.info/michigan-online-casino/ boom casino online

Perfectly spoken of course. !

online casino schweiz erfahrungen https://shadowcasino.info/states/ agen sbobet casino online deposit termurah

You suggested it exceptionally well.

andre online casino https://combatcasino.info/games/ free money online casino no deposit usa

Thanks. I appreciate it!

canadian online casino that accepts paypal https://onlinecasinoindex.us/safe-online-casinos-usa/ rio casino online

Thank you, I value it!

best online casinos for real money 2023 https://mapcasino.info/online-poker-sites/ build your own online casino

Amazing a good deal of helpful info.

new online casino sign up bonus https://shadowcasino.info/review-lucky-tiger/ australian online casino roulette

Amazing quite a lot of fantastic information!

slot stars online casino https://linkscasino.info/review-ignition/ online casino instant payout no verification

Tips clearly used!!

juegos de ruleta de casino online gratis https://eseomail.com/online-casinos-minnesota/ how to start casino online

Wonderful postings, Appreciate it.

casinos gratis online sin descargar https://usagamblingexperts.com/real-money-craps/ online casino like funzpoints

You said that well.

piggs peak online casino https://mgmonlinecasino.us/las-atlantis-review/ online vip casino

With thanks! I like it!

casino online georgia https://casinoshaman.com/online-casino-west-virginia/ online casino ohne ausweis

Great advice. Many thanks!

888 online casino download https://hotgamblingguide.info/illinois-online-casinos/ la online casino

Incredible all kinds of amazing tips!

online casino bonuses in india https://shadowcasino.info/bitcoin-casino/ online casino fair

Lovely material, Thank you.

eldorado casino online https://casinonair.com/soccer-betting/ nr 1 online casino

Thanks a lot! I enjoy it!

free bonus online casino games https://buckscasino.info/colorado-online-casinos/ best casino online india

Kudos, I appreciate this.

neue online casino mit startguthaben https://hotgamblingguide.info/no-deposit-bonus-casino/ mejores casinos en vivo online

You actually revealed this exceptionally well.

online casinos with paypal https://buckscasino.info/fast-payout-casinos/ casino online forums

Thanks a lot! A lot of information.

aspers casino online login https://igamingcasino.info/new-york-online-casinos/ online casino 200 bonus

Factor well used!.

mejor casino online panama https://riggambling.com/betting-apps/ online casino instant payout no verification

Great stuff, Appreciate it!

can online casinos be rigged https://snipercasino.info/ online casino secrets

Nicely put, With thanks.

new online casino pa 2021 https://eseomail.com/bet-on-ufc/ is harrahs casino online legit

Very good stuff. Appreciate it!

best usa online casino fast payout https://hotgamblingguide.org/states/ 400 bonus online casino

Beneficial material. Many thanks!

what are the best online casino games https://hotgamblingguide.org/cafe-casino-bonus-codes/ free casino slot games online

You actually said that wonderfully.

online casino mit boku bezahlen https://hotgamblingguide.info/online-video-poker-game/ online casino laws

You actually said this superbly.

circus casino online https://casinoslotssaid.com/play-in-an-ethereum-casino/ online casino russian

Whoa quite a lot of superb tips!

best online casino blackjack https://snipercasino.info/online-bingo/ evolution online casino

Cheers! I value this.

welches online casino zahlt am besten https://eseomail.com/new-online-casino-no-deposit-bonus-usa/ play casino slots online for real money

Amazing tips. Thanks a lot.

new online casino sign up bonus https://usagamblingexperts.com/online-poker-sites/ bandar sbobet casino online deposit termurah

Amazing a lot of valuable advice!

casino online minimum deposit 1 https://usagamblingexperts.com/video-poker-online/ casino en chile online

You’ve made your position very effectively..

chicken ranch casino online https://eseomail.com/wild-casino-review/ free online casino games with no download

Thanks a lot, Good stuff!

online mobile casino no deposit https://casinoslotoking.com/bingo-win-real-money/ singapore online live casino

Awesome posts, Regards!

uk online casinos no deposit bonus https://casinocashstars.com/virginia-online-casino/ nude online casino

Very good stuff. Regards.

germany online casinos https://casinoslotoking.com/cafe-casino-no-deposit/ casino online cu bonus fara depunere

You reported that adequately.

new online casinos usa players https://casinonair.com/golf-betting/ nj betfair online casino

With thanks! I appreciate this!

all british online casino https://riggambling.com/states/ somalia online casinos

Nicely put, Thanks!

10 best online the water wheel casinos https://magicalcasino.info/review-reddog/ playlive pa online casino

Wow plenty of awesome data!

casino online payment methods https://casinosonlinenew.com/online-casino-minnesota/ best cashtocode online casino

Kudos! Awesome information!

188 online casino https://casinocashstars.com/review-cafe/ online casino fraud detection

Thanks a lot. An abundance of facts.

gute online casino spiele https://ratingcasino.info/banking/ online backgammon casino

7ymld7

¡Hola gammers!

Descubre los bonos de 10 euros gratis sin depГіsito. winzingo 10 euros gratis Diferentes casinos te los ofrecen para que empieces a jugar sin gastar nada. ВЎRegГstrate y gana!

Activa tu bono de 10 euros sin depГіsito en el casino online. Disfruta de todos los juegos y gana dinero real sin invertir. ВЎEmpieza ya mismo!

Toda la información en el enlace – п»їhttps://10eurosgratissindepositocasino.xyz/

¡Que tengas buenos bonos!

¡Hola cazadores de adrenalina!

En 2025 los mejores casinos online siguen regalando 10 euros sin depГіsito. gana 10 euros por registrarte RegГstrate y juega gratis sin preocuparte por tu saldo. ВЎAprovecha!

Aprovecha un bono sin depГіsito de 10 euros gratis. RegГstrate y empieza a jugar sin poner un solo euro. Perfecto para conocer el casino antes de invertir.

Toda la información en el enlace – п»їhttps://10eurosgratissindepositocasino.xyz/

¡Que tengas buenos ganancias!

¡Hola cazadores de adrenalina!

Consigue 10€ gratis para jugar en los mejores casinos online. regГstrate y 10 euros gratis No necesitas hacer ningГєn depГіsito. Solo crea tu cuenta y el bono serГЎ tuyo. Juega, diviГ©rtete y gana sin gastar un solo euro.

Juega en un casino espaГ±ol con 10 euros gratis sin depГіsito. Todo lo que necesitas es registrarte. Empieza hoy mismo y prueba tu suerte gratis.

Toda la información en el enlace – п»їhttps://10eurosgratissindepositocasino.xyz/

¡Que tengas buenos tragaperras!

¡Hola apostadores!

ВїQuieres jugar sin gastar? bingo 10 euros gratis sin depГіsito Reclama 10 euros gratis sin depГіsito en tu casino online favorito. Disfruta de tus juegos preferidos y retira tus ganancias cuando ganes. Solo necesitas registrarte y el bono es tuyo.

RegГstrate hoy y recibe 10 euros gratis para jugar en los mejores casinos online. Sin depГіsitos, sin riesgos. Solo diversiГіn y premios reales. Es la forma perfecta de empezar a jugar sin preocuparte por tu bolsillo.

Toda la información en el enlace – п»їhttps://10eurosgratissindepositocasino.xyz/

¡Que tengas buenos juegos!

Hi joke lovers!

These puns bring the fast break of funny. basketball puns

Steal some smiles with basketball play on words that pass the vibe check. Fast breaks, faster laughs.

Toda la información en el enlace – п»їhttps://basketballpuns.com/

Here’s to plenty of hilarious moments!

Hi if you’re laughing, you’re in!

Game face on, joke mode activated. basketball puns

Slam dunk your next caption with funny basketball puns. Because every baller deserves some wordplay.

Toda la información en el enlace – п»їhttps://basketballpuns.com/

Here’s to plenty of comic brilliance!

Hi pun appreciators!

Pun power activated—prepare for a comedy crossover. basketball puns

Drop some heat with basketball one liners that never miss. Fast laughs, smooth delivery.

Toda la información en el enlace – п»їhttps://basketballpuns.com/

Here’s to plenty of laugh-out-louds!

Hi comedy enthusiasts!

Bring the laughs to your next hangout with basketball pun one liners that always score high with the crowd. basketballpuns

Slam dunk your next caption with funny basketball puns. Because every baller deserves some wordplay.

Toda la información en el enlace – п»їhttps://basketballpuns.com/

Here’s to plenty of laugh-out-louds!

Hi if you’re laughing, you’re in!

Get into the game with puns funny basketball jokes designed to entertain players and pun fans alike. basketball dad jokes No warm-up needed.

Bounce into laughter with basketball.puns that are funnier than a mascot in a dunk contest. Get your daily dose of hoops humor.

Toda la información en el enlace – п»їhttps://basketballpuns.com/

Here’s to plenty of smiles!

Hi joke lovers!

Basketball dad jokes so bad… they’re actually great. basketballpuns.com Get ready to groan, giggle, and maybe high-five your inner dad.

Looking for basketball dad jokes? These are the MVPs of lame-but-lovable humor. No court required, just a love for laughs.

Toda la información en el enlace – п»їhttps://basketballpuns.com/

Here’s to plenty of laugh-out-louds!

Hi fans of humor!

Bring the laughs to your next hangout with basketball pun one liners that always score high with the crowd. puns funny basketball jokes

Basketball love puns that’ll have your heart doing layups. For romantics who think love is better with a scoreboard.

Toda la información en el enlace – п»їhttps://ontheborder.com.au/the-history-of-tequila/#comment-2550

Wishing you lots of bursting emotions!

Hi if you’re laughing, you’re in!

Spice up your convo with basketball.puns that dribble straight into your funny bone. [url=https://talkingindia.in/finance/full-form-of-tdo/#comment-77236]п»їbasketball puns[/url] Game on, laugh strong.

Basketball dad jokes that even the coach can’t bench. Pure pun-ishment in the best way.

Toda la información en el enlace – https://talkingindia.in/finance/full-form-of-tdo/#comment-77236

Wishing you lots of bursting emotions!

Hi if you’re laughing, you’re in!

From tip-off to overtime, these basketball play on words never miss. basketball.puns It’s game time for your sense of humor.

Calling all hoop heads: basketball love puns are here to make your heart dribble. Swipe right on slam dunks and smiles.

Toda la información en el enlace – https://talkingindia.in/finance/full-form-of-tdo/#comment-77236

Wishing you lots of funny moments!

Hi pun appreciators!

Steal some smiles with basketball play on words that pass the vibe check. basketball puns one liners Fast breaks, faster laughs.

Serve up some spice with basketball food puns. From nacho average jokes to slam-dunking snacks, they’re deliciously funny.

Toda la información en el enlace – https://talkingindia.in/finance/full-form-of-tdo/#comment-77236

Wishing you lots of giggles!

¡Hola expertos en apuestas

Los pagos en casinos sin licencia son mГЎs rГЎpidos y directos. casinossinlicenciaenespana Puedes recibir tus ganancias en minutos, sin pasar por largas verificaciones.

Casinos sin licencia de EspaГ±a permiten depГіsitos mГnimos bajos. Es una buena forma de empezar sin arriesgar mucho. Ideal para nuevos jugadores que quieren probar.

Consulta el enlace para más información – п»їhttps://casinossinlicenciaenespana.guru/

¡Por muchos carcajadas!

¡Hola expertos en apuestas

El bono de bienvenida en casinos sin licencia puede ser mГЎs alto que en los regulados. casinossinlicenciaenespana Aprovecha estas promociones al registrarte.

Una plataforma de apuestas sin licencia puede operar en mГєltiples paГses con una sola licencia internacional. Esto facilita su expansiГіn y acceso global. Verifica si aceptan usuarios de EspaГ±a antes de registrarte.

Consulta el enlace para más información – http://casinossinlicenciaenespana.guru/

¡Por muchos sonrisas!

¡Hola aficionados al casino

Los pagos en casinos sin licencia tienden a ser mГЎs flexibles. Puedes usar mГ©todos como Bitcoin, Ethereum o tarjetas prepagadas. casinossinlicenciaenespana Revisa si hay comisiones asociadas.

Los casinos sin licencia en EspaГ±a permiten a los jugadores registrarse rГЎpidamente y comenzar a jugar sin procesos complicados. Muchos sitios aceptan criptomonedas y otros mГ©todos modernos. Es una opciГіn ideal para quienes valoran la eficiencia.

Consulta el enlace para más información – п»їhttps://casinossinlicenciaenespana.guru/

¡Por muchos brillantez cómica!

¡Hola aventureros del juego

EspaГ±a sin licencia es un concepto que atrae a muchos jugadores por la libertad que implica. Puedes acceder a mГЎs juegos, bonos y mГ©todos de pago. https://casinossinlicenciaenespana.guru Pero siempre hay que investigar antes de depositar.

Puedes apostar en casinos sin licencia desde tu mГіvil o tablet sin problemas. La mayorГa son compatibles con dispositivos Android e iOS. Verifica si tienen app o versiГіn optimizada.

Consulta el enlace para más información – http://casinossinlicenciaenespana.guru/

¡Por muchos brillantez cómica!

jfbjoh

Hi, i think that i saw you visited my website thus i got here to “go back the desire”.I am trying to in finding things to enhance my website!I suppose its adequate to make use of some of your ideas!!

lzz2x9

?Hola usuarios de apuestas

Esto facilita resolver cualquier duda rГЎpidamente.

Las mejores pГЎginas de apuestas EspaГ±a incluyen tanto sitios con licencia como opciones internacionales. Lo importante es que sean seguras, rГЎpidas y con buena atenciГіn al cliente.

Mejores casas de apuestas espaГ±olas con interfaz limpia – п»їhttps://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes botes acumulados!

?Hola apostadores apasionados

casasdeapuestassinlicenciaespana

Las casas de apuestas legales en EspaГ±a estГЎn reguladas por la DGOJ, pero eso no significa que sean la Гєnica opciГіn. Muchos jugadores prefieren sitios internacionales por sus ventajas.

Mejores casas no reguladas con bonos sin depГіsito – http://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes partidas!

?Hola apostadores apasionados

AsГ podrГЎs jugar lo que quieras sin cambiar de cuenta.

Entre las mejores casas de apuestas espaГ±olas se encuentran algunas nuevas, con interfaz moderna y sin requisitos complejos de registro.

Casas de apuestas sin lГmites de retiro ni verificaciГіn – http://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes ventajas!

?Hola fanaticos del casino

Ofrecen mГЎs variedad de juegos y menos restricciones de retiro.

Las casas de apuestas en EspaГ±a sin licencia local no estГЎn sujetas a lГmites de apuestas o restricciones de bonos. Perfectas para jugadores VIP.

Casas de apuestas seguras con cifrado SSL y licencias reales – https://casasdeapuestassinlicenciaespana.xyz/#

?Que tengas excelentes exitos!

?Hola jugadores

ВїPrefieres no dar datos personales? Las casas de apuestas sin verificaciГіn eliminan esa barrera.

ВїBuscas apuestas sin depГіsito mГnimo? Hay plataformas que ofrecen apuestas desde 0,10€, perfectas para jugadores nuevos.

Casas extranjeras para apuestas sin DNI ni lГmites – http://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes botes acumulados!

?Hola usuarios de apuestas

Con una cuenta en casas de apuestas internacionales, accedes a mercados mГЎs amplios y bonos mГЎs altos.

Una plataforma de apuestas sin licencia puede ser ideal para jugadores experimentados que buscan mejores cuotas y menos limitaciones.

ВїSon fiables las casas de apuestas sin registro en EspaГ±a? – http://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes exitos!

?Hola apostadores apasionados

Los bonos en las casas de apuestas sin verificaciГіn se activan sin necesidad de enviar documentos.

Una casa de apuestas fiable puede no tener licencia espaГ±ola, pero operar legalmente bajo otras leyes internacionales.

Casas de apuestas online EspaГ±a: plataformas seguras y legales – https://casasdeapuestassinlicenciaespana.xyz/#

?Que tengas excelentes botes acumulados!

?Hola apostadores apasionados

casasdeapuestassinlicenciaespana

Las casas de apuestas seguras sin licencia utilizan protocolos como SSL, cifrado de datos y soporte 24/7 para garantizar tu tranquilidad.

Casas apuestas legales EspaГ±a: lГmites y condiciones – https://casasdeapuestassinlicenciaespana.xyz/#

?Que tengas excelentes partidas!

?Hola aventureros del azar

Son comunes entre los operadores internacionales.

En casas apuestas sin licencia, puedes evitar los largos procesos de KYC y disfrutar de una experiencia rГЎpida y directa.

Casas de apuestas con licencia en EspaГ±a: guГa oficial – п»їhttps://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes partidas!

?Hola usuarios de apuestas

Solo crea una cuenta y empieza a apostar.

ВїBuscas apuestas sin depГіsito mГnimo? Hay plataformas que ofrecen apuestas desde 0,10€, perfectas para jugadores nuevos.

Mejores casas no reguladas con bonos sin depГіsito – http://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes slots!

?Hola fanaticos del casino

casasdeapuestassinlicenciaespana

Una casa de apuestas espaГ±ola puede ser una excelente opciГіn, pero no descartes explorar otras con licencias extranjeras. Comparar te darГЎ mГЎs beneficios.

Apuestas deportivas sin DNI y sin complicaciones – п»їhttps://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes premios!

?Hola usuarios de apuestas

Y lo mejor: sin necesidad de verificaciГіn inmediata.

Una casa de apuestas espaГ±ola puede ser una excelente opciГіn, pero no descartes explorar otras con licencias extranjeras. Comparar te darГЎ mГЎs beneficios.

Casas apuestas sin licencia con promociones constantes – п»їhttps://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes premios!

?Hola aventureros del azar

Las internacionales te dan mГЎs libertad y opciones de pago.

Elige una casa de apuestas sin restricciones si quieres jugar sin lГmites de apuestas ni topes en retiros. Todo depende de ti.

Casas de apuestas fiables: cГіmo elegir las mejores – https://casasdeapuestassinlicenciaespana.xyz/#

?Que tengas excelentes partidas!

?Hola entusiastas del juego

Las mejores casas de apuestas espaГ±olas no siempre tienen licencia DGOJ.

Las casas de apuestas con licencia en EspaГ±a tienen mГЎs limitaciones. Las internacionales, por el contrario, ofrecen una experiencia mГЎs flexible y personalizada.

Casas apuestas legales EspaГ±a: lГmites y condiciones – п»їhttps://casasdeapuestassinlicenciaespana.xyz/

?Que tengas excelentes ventajas!

?Hola fanaticos del casino

La mejor pГЎgina de apuestas online serГЎ la que se adapte a tu estilo.

ВїExisten casas de apuestas fiables sin licencia? ВЎSГ! Muchas operan bajo licencias de Curazao o Malta, con sistemas de protecciГіn avanzados y pagos rГЎpidos. La clave estГЎ en elegir bien.

Casas de apuestas seguras con cifrado SSL y licencias reales – casas de apuestas sin licencia.

?Que tengas excelentes ventajas!

Informasi akses situs Sigma slot

?Hola usuarios de apuestas

п»їMuchas personas estГЎn optando por casas de apuestas sin DNI porque permiten jugar de forma inmediata y sin complicaciones. Sitios como casasapuestassindni.xyz facilitan el acceso sin necesidad de enviar documentaciГіn, lo que hace que todo el proceso sea mucho mГЎs ГЎgil. AdemГЎs, estas casas de apuestas sin registro dni permiten apostar sin registrarse, ideal para quienes no quieren dejar sus datos personales.

casas de apuestas sin dni sin requisitos – casas apuestas sin dni

?Que tengas excelentes partidas!

?Hola fanaticos del casino

Casasapuestassindni.xyz agrupa en un solo sitio las principales casas sin verificaciГіn, ideales para jugadores que quieren libertad total. Con actualizaciones frecuentes y anГЎlisis detallados.

casas de apuestas sin verificaciГіn inmediata – casas apuestas sin dni

?Que tengas excelentes exitos!

?Hola participantes de casino

Gracias a plataformas como casasapuestassindni.xyz, ahora es posible apostar sin dni incluso en vivo, en deportes como fГєtbol, tenis, baloncesto o eSports. La acciГіn no se detiene nunca.

CasasApuestasSinDni con bonos 2025 – casas apuestas sin dni

?Que tengas excelentes botes acumulados!

¡Hola competidores de casino

ObtГ©n acceso a bonos exclusivos sin requisitos complicados. casas de apuestas fiables

Algunas casas de apuestas internacionales ofrecen versiones demo de todos sus juegos, sin necesidad de registro.

ВїDГіnde apostar sin KYC ni verificaciГіn? – apuesta en las mejores casas de apuestas sin licencia en España

¡Por muchos momentos de risa!

?Hola fanaticos del casino

CasasApuestasSinDni es una excelente alternativa si lo que buscas es jugar sin limitaciones. Las casas apuestas sin dni que aquГ se presentan no solo son fГЎciles de usar, sino que tambiГ©n ofrecen promociones constantes para usuarios nuevos y frecuentes.

п»їcasas de apuestas sin dni en 2025 – http://casasapuestassindni.xyz/

?Que tengas excelentes premios!

?Hola participantes de casino

Las casas de apuestas sin verificaciГіn tambiГ©n permiten acceder a bonos de bienvenida, cashback semanal y giros gratis sin necesidad de registrarte. En https://casasapuestassindni.xyz/ puedes ver cuГЎles ofrecen las mejores recompensas.

CasasApuestasSinDni 2025 confiables – casas de apuestas sin dni

?Que tengas excelentes slots!

?Hola apostadores apasionados

Apostar sin dni se ha vuelto tendencia entre quienes buscan comodidad y anonimato. Al ingresar a https://casasapuestassindni.xyz/ puedes elegir entre varias plataformas donde no se requiere verificaciГіn ni datos personales para jugar. Todo el proceso se realiza en segundos.

apuestas online sin registro 2025 – casasapuestassindni.xyz

?Que tengas excelentes ventajas!

?Hola entusiastas del juego

Las casas de apuestas sin verificaciГіn tambiГ©n permiten acceder a bonos de bienvenida, cashback semanal y giros gratis sin necesidad de registrarte. En https://casasapuestassindni.xyz/ puedes ver cuГЎles ofrecen las mejores recompensas.

casas de apuestas sin dni sin verificaciГіn – casasapuestassindni.xyz

?Que tengas excelentes botes acumulados!

?Hola apostadores apasionados

Si lo tuyo son los juegos rГЎpidos y sin compromisos, apostar sin dni es la mejor opciГіn. En http://casasapuestassindni.xyz/ encuentras casas sin registro que te permiten entrar, jugar y salir cuando quieras, sin dar explicaciones. Puedes acceder a tragamonedas, ruleta, blackjack y apuestas online sin registro fГЎcilmente.

apuestas deportivas sin dni ahora – casasapuestassindni.xyz

?Que tengas excelentes partidas!

?Hola jugadores

Las casas de apuestas sin verificaciГіn tienen una ventaja clara sobre las reguladas: no te obligan a justificar tus ingresos ni controlar tus movimientos. Juegas lo que quieres, cuando quieres.

CasasApuestasSinDni sin KYC – casasapuestassindni.xyz

?Que tengas excelentes slots!

?Hola apostadores apasionados

Una de las grandes ventajas de las casas de apuestas sin registro dni es que no necesitas descargar nada ni completar formularios largos. Solo eliges tu juego y empiezas. Sitios como http://casasapuestassindni.xyz/ estГЎn enfocados en ofrecer una experiencia rГЎpida, segura y sin barreras. AdemГЎs, permiten apostar sin registrarse, ideal para quienes valoran el tiempo.

apuestas deportivas sin dni al momento – casasapuestassindni.xyz

?Que tengas excelentes premios!

?Hola jugadores

Las apuestas deportivas sin dni no tienen nada que envidiar a las reguladas. Cuotas competitivas, mercados variados y acceso inmediato hacen que cada vez mГЎs personas las prefieran.

casas de apuestas sin verificaciГіn real – casa de apuestas sin dni

?Que tengas excelentes botes acumulados!

?Hola apostadores apasionados

Una de las grandes ventajas de las casas de apuestas sin registro dni es que no necesitas descargar nada ni completar formularios largos. Solo eliges tu juego y empiezas. Sitios como http://casasapuestassindni.xyz/ estГЎn enfocados en ofrecer una experiencia rГЎpida, segura y sin barreras. AdemГЎs, permiten apostar sin registrarse, ideal para quienes valoran el tiempo.

п»їcasas de apuestas sin dni en 2025 – casa de apuestas sin dni

?Que tengas excelentes botes acumulados!

?Hola usuarios de apuestas

CasasApuestasSinDni te da acceso a bonos exclusivos sin necesidad de validar tu identidad. Puedes apostar sin registrarte en muchos casos. CasasApuestasSinDni AsГ, la experiencia es mucho mГЎs rГЎpida y privada.

Si prefieres apostar sin registrarte y sin tener que subir una selfie con tu DNI, estas casas son ideales. Solo necesitas una conexiГіn a internet y ganas de jugar. Todo lo demГЎs es opcional.

apostar sin registrarse de forma fГЎcil – casas apuestas sin dni

?Que tengas excelentes exitos!

?Hola apostadores apasionados

Disfruta de experiencias Гєnicas con juegos poco convencionales. apuestas deportivas sin dni

Los torneos de apuestas con premios en cripto o NFT son comunes en casas fuera del circuito DGOJ.

Casas de apuestas sin licencia: juegos en vivo – casas de apuestas sin licencia en España

?Que tengas excelentes botes acumulados!

?Hola apostadores apasionados

usando solo un correo electrГіnico y una contraseГ±a segura.

Las apuestas en vivo se disfrutan mГЎs con menos lag y mГЎs libertad, justo lo que ofrecen estas plataformas.

Casas sin licencia: juega sin dejar rastro – casas de apuestas sin licencia en España

?Que tengas excelentes partidas!

?Hola entusiastas del juego

ВїQuieres apostar sin lГmites de retiro? AquГ puedes hacerlo. casas de apuestas sin verificacion

ВїTe gustarГa recibir bonos en funciГіn de tu actividad? Las casas sin licencia tienen programas de fidelidad muy generosos.

Apuestas sin licencia: riesgos y beneficios – casas de apuestas sin licencia en España

?Que tengas excelentes slots!

?Hola jugadores

casas apuestas online espaГ±a

A diferencia de las casas reguladas, las internacionales pueden ofrecer apuestas en deportes menos comunes o ligas alternativas.

Casas de apuestas sin licencia: pros y contras – casas de apuestas sin licencia en España

?Que tengas excelentes botes acumulados!

?Hola jugadores

Juega con anonimato completo usando mГ©todos alternativos de pago. casas de apuestas con licencia en espaГ±a

Las casas sin licencia pueden ofrecer bonos sin rollover, lo que significa que puedes retirar tus ganancias sin dar vueltas.

Casas de apuestas sin licencia: cГіmo identificarlas – casas de apuestas sin licencia en España

?Que tengas excelentes botes acumulados!

?Hola jugadores

Aprovecha 20 euros gratis retirables y juega sin preocuparte de perder tu dinero.

Casino Barcelona: 20 tiradas gratis para nuevos usuarios – casino20eurosgratissindeposito.guru

?Que tengas excelentes exitos!

?Hola exploradores del azar

Con Playzax casino 20 euros gratis podrГЎs disfrutar de juegos emocionantes y ganar dinero real sin hacer depГіsitos. ВЎRegГstrate y empieza hoy mismo!

Casino Barcelona: 20 tiradas gratis para nuevos usuarios – ganar 20 euros por registrarte

?Que tengas excelentes premios gordos !

¡Hola buscadores de emociones !

Cada casino tiene diferentes juegos para usar tus giros gratis. 100 giros gratis sin depГіsito DescГєbrelos todos.

ВїYa conoces la promociГіn de 100 giros gratis sin depГіsito 2025? Es ideal para probar nuevos tГtulos sin arriesgar tu saldo. Disponible en casinos seleccionados.

Gira y gana con 100 giros gratis sin condiciones – https://100girosgratissindepositoespana.guru/#

¡Que tengas magníficas rondas inolvidables !

Вам требуется лечение? https://chemodantour.ru лечение хронических заболеваний, восстановление после операций, укрепление иммунитета. Включено всё — от клиники до трансфера и проживания.

цена ноутбука для работы где купить ноутбук

смартфоны 2024 года цены смартфон poco купить

печать наклеек этикеток печать маленьких наклеек

Всегда есть что-то интересное из актуального порно онлайн:

17 летние девушки порно

ГГУ имени Ф.Скорины https://www.gsu.by/ крупный учебный и научно-исследовательский центр Республики Беларусь. Высшее образование в сфере гуманитарных и естественных наук на 12 факультетах по 35 специальностям первой ступени образования и 22 специальностям второй, 69 специализациям.

Francisk Skorina https://www.gsu.by Gomel State University. One of the leading academic and scientific-research centers of the Belarus. There are 12 Faculties at the University, 2 scientific and research institutes. Higher education in 35 specialities of the 1st degree of education and 22 specialities.

Create vivid images with Promptchan — a powerful neural network for generating art based on text description. Support for SFW and NSFW modes, style customization, quick creation of visual content.

Недвижимость в Болгарии у моря https://byalahome.ru квартиры, дома, апартаменты в курортных городах. Продажа от застройщиков и собственников. Юридическое сопровождение, помощь в оформлении ВНЖ, консультации по инвестициям.

Срочный выкуп квартир https://proday-kvarti.ru за сутки — решим ваш жилищный или финансовый вопрос быстро. Гарантия законности сделки, юридическое сопровождение, помощь на всех этапах. Оценка — бесплатно, оформление — за наш счёт. Обращайтесь — мы всегда на связи и готовы выкупить квартиру.

Портал о недвижимости https://akadem-ekb.ru всё, что нужно знать о продаже, покупке и аренде жилья. Актуальные объявления, обзоры новостроек, советы экспертов, юридическая информация, ипотека, инвестиции. Помогаем выбрать квартиру или дом в любом городе.

цветы спб купить цветы питер

цветы дешево цветы на дом

Всегда есть что-то интересное из актуального порно онлайн:

видео детского порно

мастерская цветов заказать букет цветов с доставкой в спб

натяжные потолки м https://natyazhnye-potolki-moskva1.ru

дипломная работа срочно на заказ заказать дипломная работа

написание рефератов на заказ написание реферата

Гид в Калининграде цена https://gid-po-kaliningradu.ru – узнайте стоимость.

рефераты на заказ написание реферата

дипломная работа купить заказать дипломная работа

гардина для натяжного потолка парящие натяжные потолки цена

прокат авто на сутки прокат авто круглосуточно

прокат авто сайт прокат авто

Эта статья предлагает захватывающий и полезный контент, который привлечет внимание широкого круга читателей. Мы постараемся представить тебе идеи, которые вдохновят вас на изменения в жизни и предоставят практические решения для повседневных вопросов. Читайте и вдохновляйтесь!

Углубиться в тему – https://medalkoblog.ru/

сколько стоят экскурсии в калининграде индивидуальные экскурсии в калининграде

сделать натяжной потолок квартире сделать натяжной потолок квартире .

сайт на laravel разработка сайта магазина минск

шильдик на пиджак изготовление металлических шильдиков в москве

заказ бейджей металлические бейджи с эмалью изготовление

шильды латунные шильды на заказ москва

шильд латунь шильд изготовить москва

продвижение сайта купить продвижение сайта в топ 10

бейджи изготовление изготовление бейджиков

изготовление металлических значков изготовление металлического значка

значки из металла на заказ москва изготовление железных значков

поисковое продвижение seo оптимизация сайта стоимость

значки на заказ металлические металлические значки под заказ

поисковое продвижение сайта продвижение сайта москва

типография официальный сайт типография цена

типография сколько типография недорого

типография производство типография изготовление

типография печать визиток печать визиток на пластике

типография печать визиток заказать печать визиток

Нужна печать наклеек? Закажите стикеры любых форм и размеров с доставкой. Яркие, прочные, влагостойкие наклейки на пленке и бумаге — для рекламы, декора, маркировки и упаковки.

Профессиональная типография быстро. Изготовим любые печатные материалы — от визиток до каталогов. Качественно, быстро, с гарантией. Закажите онлайн или приезжайте в офис в СПб.

Изготовление и печать наклейки на заказ спб. Стикеры для бизнеса, сувениров, интерьера и упаковки. Печатаем тиражами от 1 штуки, любые материалы и формы. Качественно, недорого, с доставкой по СПб.

Безболезненная https://lazernaya-epilyaciya33.ru Удаление волос на любом участке тела. Работаем с чувствительной кожей, используем новейшие лазеры. Акции, абонементы, индивидуальный подход.

Удаление волос сколько стоит лазерная эпиляция: гладкая кожа на долгое время. Аппараты последнего поколения, опытные мастера, комфортная обстановка. Эпиляция для женщин и мужчин. Онлайн-запись, гибкие цены, без лишнего стресса.

Профессиональная лазерная эпиляция лазером спб. Эффективное удаление волос на любом участке тела, подход к любому фототипу. Сертифицированные специалисты, стерильность, скидки. Запишитесь прямо сейчас!

частная клиника адрес медицинского центра

Избавьтесь от волос https://lazernaya-epilyaciya-spb5.ru навсегда — с помощью лазерной эпиляции. Эффективные процедуры на любом участке тела, минимальный дискомфорт, заметный результат уже после первого сеанса.

купить софт купить программное обеспечение лицензия

доставка цветов на дом купить цветы в спб

кабинет узи https://uzi-abakan11.ru

дерматологи абакана отзывы дерматолог абакан

клиника диагностика https://medicinskiy-centr-abakan11.ru

хороший платный терапевт обратиться к терапевту

Свежие актуальные новости мира спорта со всего мира. Результаты матчей, интервью, аналитика, расписание игр и обзоры соревнований. Будьте в курсе главных событий каждый день!

birthday balloons delivery dubai ribbons and balloons dubai

resume for engineering jobs cv engineer resume

Рокли с колан за подчертаване на талията и женствените извивки

ежедневни рокли https://www.rokli-damski.com/ .